Work Plan

WP1 | Definition of system requirements in relation to value chain

Duration: M1 — M6

Lead Beneficiary: SYPOX

Goals:

Definition of key requirements for a successful scale-up for the e‑SMR

Definition of boundary conditions for the installation of Pilot 1(syngas producing plant)

Definition of boundary conditions for the installation of Pilot 2 (hydrogen producing plant)

Definition of a business model for the production of renewable hydrogen from biogas

WP2 | Integrated design of the catalytic electrically-heated reactor

Duration: M7 — M42

Lead Beneficiary: TUM

Goals:

Preparation, testing, and characterization of innovative reforming catalyst formulations

Heat and mass transfer measurements

CFD and engineering models of the electrified reformer

Testing of the scaled-up catalysts in a 25-kW e‑SMR setup and model validations

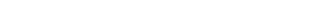

WP3 | Scale-up and validation of the reformer at TRL 6

Duration: M4 — M27

Lead Beneficiary: TUM

Goals:

Design of the 250-kW e‑SMR

Permission/authorization required for installation

Plant design, procurement, and construction

Start-up and operation of the pilot

Reactor and catalyst scale up validation

Flexibility of the e‑SMR: sector coupling validation

WP4 | Construction of complete H2 producting pilot and validation at TRL6

Duration: M6 — M42

Lead Beneficiary: HYGEAR

Goals:

Development, design and manufacturing of an autonomous operating renewable H2 producing skid, integrated in a 40 ft shipping container.

The design of the pilot will integrate the e‑SMR.

Producing ~200 nm3/h fuel cell grade H2

Site design and preparations and permissions for installation and demonstration of the H2 producing pilot at a biogas plant in Dollnstein, Germany.

Validation of the H2 producing pilot at TRL6

WP5 | Permissions/Authorisations, Conformities, Safety, LC(S) Assessments, social impact

Duration: M7 — M42

Lead Beneficiary: BUREAU VERITAS

Goals:

Identification of all applicable laws and standards

Process Safety and conformities for e‑SMR

Techno-economic, LCA and S‑LCA assessments

Certification scheme in perspective of project replication

WP7 | Upscaling of e‑SMR reactor and integration of e‑SMR in larger plants for centralized applications

Duration: M7 — M42

Lead Beneficiary: Linde GmbH

Goals:

Develop basis of process design

Develop concepts for process integration

Perform techno-economic analysis of e‑SMR for larger applications

Evaluate modification of reactor design

Evaluate reactor parallelization

EReTech

Grant agreement ID: 101058608

Start date 1 June 2022

End date 30 November 2025